In Spring 2021, CoMotion announced eight Innovation Gap Fund winners across multiple disciplines from life sciences to engineering and social work. Each award winner received up to $50,000 to support research projects through the “valley of death,” a time that is especially challenging for early entrepreneurs as they work to advance their research from being academically-focused into something commercially viable and compelling for private capital investments.

This month, we’re highlighting three award winners, Smart Paper, Detecting 3D Printing Defects, and DeepTracer, to share more about their stories, innovations, and impact.

For more information about the CoMotion Innovation Gap Fund and to view the complete list of winners, see our June blog post. To stay informed of future highlights, sign up for our newsletter and follow us on Twitter and LinkedIn.

Smart Paper

Conductive paper is used in a variety of applications, from electronics to energy storage devices. To make paper conductive, however, most manufacturers apply an external coating of conductive carbon nanotubes. This creates a rough exterior surface that does not always conduct electricity reliably. Now, thanks to Anthony Dichiara and his team, there is a new approach.

Dichiara’s Smart Paper is a blend of carbon nanotubes and paper pulp, polar and non-polar materials respectively, that don’t mix well without a bit of chemistry. By blending the materials together, rather than applying the carbon nanotubes as an external coating, the resulting paper is more flexible and highly conductive.

While exploring potential applications, Dichiara’s efforts took a surprising turn when a student accidentally spilled water on a sample, causing it to lose its conductivity. Apologetically, the student went to throw the paper away, but Dichiara stopped him. What happened next opened the door to numerous applications; when the paper dried up, it recovered its conductivity, making it especially useful for leak detection.

After publishing these results, Dichiara and his team received an inquiry from the European Council for Nuclear Research (CERN), who wanted to use Smart Paper in its monitoring experiments. Dichiara reached out to CoMotion for IP advice and decided to protect the chemistry of the material.

Now the team is exploring other applications, from water sensing in agriculture to leak detection in homes, storage facilities, and utilities. “People were interested in detecting water for many different reasons that I wasn’t aware of before,” says Dichiara, “This is where CoMotion was really helpful, particularly with the Innovation Gap Fund competition. CoMotion helped me realize that there is real commercial potential, otherwise I’m pretty sure it would have just been another research paper with a couple of citations. CoMotion gave me the tools and the connections to talk to people and learn.”

With the Innovation Gap Fund award, Dichiara and his team plan to explore future applications and improve the prototype design.

PI:

Anthony Dichiara, Ph.D., Assistant Professor, School of Environmental and Forest Sciences

Team:

Sheila Goodman, Ph.D. Student

Innovation Manager:

Forest Bohrer

Mentor:

Ozgur Yildirim

Learn more and connect:

Dichiara Research Group

Detecting 3D Printing Defects

Despite its ability to build parts with incredible geometry, 3D printing is less stable and repeatable compared with traditional machining. Printed parts can come out differently on the same day, with the same machine, using the same CAD design. This results in significant post-processing inspection efforts.

The technology developed by Xu Chen and his team can change the game, by automatically detecting defects and evaluating part quality during the printing process. After printing is complete, the type, location, and severity of defects are immediately available to users, which can help reduce the cost of each part by 5-15%. In addition, by analyzing the characteristics of defects, the new technology can help users identify the source of the disturbance so that it can be addressed.

“As researchers in academia, we can present complex, technical algorithms and equations very well. But a truly impactful product wouldn’t be possible with a researcher alone,” says Tianyu Jiang, lead technical officer. “The CoMotion team is very resourceful. When we needed to collect feedback from the 3D printing manufacturers, one of the CoMotion team members introduced us to the right person interested in our innovation.”

Chen’s team recently increased the defect detection accuracy by more than 50% by leveraging deep neural networks. With the Innovation Gap Fund award, the team hopes to test new algorithms, reduce the length of the development cycle, consult with experts in marketing and licensing, and present their technology to a broader audience.

PI:

Xu Chen, Ph.D., Associate Professor, College of Engineering, Mechanical Engineering Department

Team:

Tianyu Jiang, Lead Technical Officer

Thomas Chu, Technical Officer

Dan Wang, Ph.D. Science Officer

Feifei Yang, Technical Officer

Jason Xie, Technical Officer

Innovation Manager:

Ryan Buckmaster

Mentor:

Paul Pomeroy

Learn more and connect:

Mechatronics, Automation, and Control Systems Laboratory

DeepTracer

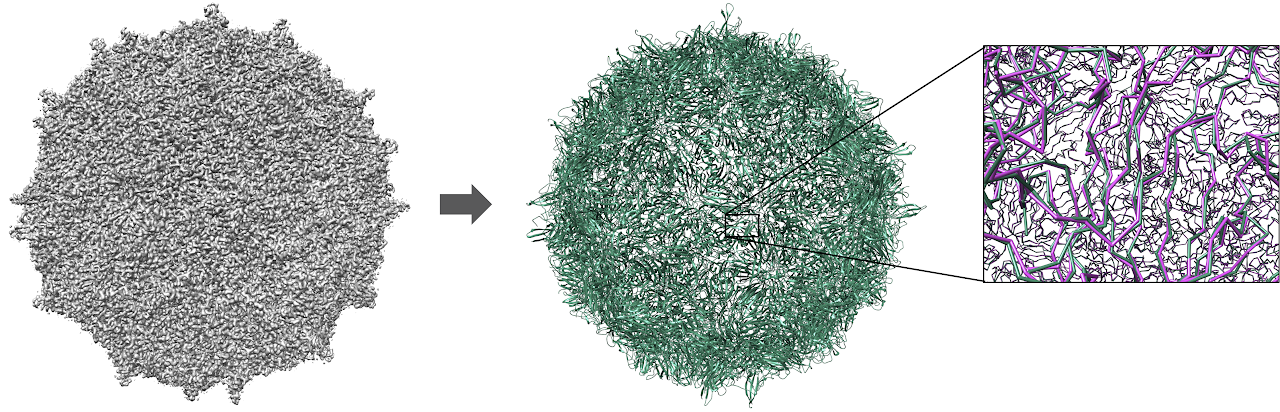

Manually, it can take months, if not years, to accurately predict the protein structure of a bacteria, virus, or large molecular machine from cryo-electron microscopy (cryo-EM) maps. Now, this can be done in just seconds, minutes, or hours, thanks to technology developed by Dong Si and his team at UW Bothell. This technology, called DeepTracer, uses deep learning to analyze 3D cryo-EM maps. The easy-to-use platform traces the atom’s connections, creating an accurate model of the structure. This provides key information for developing drugs and vaccines that are both timely and effective.

Although DeepTracer can model the structure of any bacteria, virus, or large molecular machine, its ability to quickly and accurately decipher and model SARS-CoV-2 caught the attention of researchers and news media in the fight against COVID-19. Weekly, Dong Si and his team update the CoV-related modeling created by running DeepTracer on the latest source data.

Si credits CoMotion for connecting him with numerous resources and learning opportunities saying, “I’ve really learned a lot about licensing, commercialization, industry, and the world. When you are too focused on the research and academia, you don’t think about the possibilities, plans, and futures in the industry, and what impact you can make in the world.” With the Innovation Gap Fund award, Dong Si hopes to increase awareness of DeepTracer and further develop the backend server and the desktop interface to improve its functionality.

PI:

Dong Si Ph.D., Assistant Professor, Computing and Software Systems Division of STEM, UW Bothell

Team:

Jonas Pfab, Lead Engineer

Yinrui (Bobby) Deng, Lead System Engineer

Michael Chavez, Senior Backend Developer

Hanze Meng, System Engineer

Innovation Manager:

Laura Dorsey

Mentor:

Todd Smith

Learn more and connect:

DeepTracer

Data Analysis & Intelligent Systems (DAIS) Group

Twitter:

@deeptracer

@DAIS_research